ABOUT DCAFOCUSMANUFACTURING CAPABILITY

- Woman owned small business

- Privately held corporation, Majority stock holder Martha Richardson Minority stock holder Paul Richardson.

- Incorporated in 1982, acquired in 1999

- 14,000 square foot facility in Hampstead NH

- ISO 9000: 1000 registered

- Services provided include, transformers, circuit cards, assemblies, cables, wire harnesses, and box build assemblies

- Unequaled customer satisfaction

- Prototype/Repair team ready on a 24 hour notice for rapid prototyping of new products and re-work of circuit card assemblies

- Small/Medium production runs turn-key or consignment kits

- Transformers from 1 to 12,000 a year

- Cables/Harnesses from 1 to 1000 per month capability

- Box builds from commercial and government partners

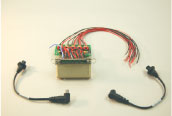

TRANSFORMERS

CIRCUIT CARD ASSEMBLIES

WIRE HARNESS ASSEMBLY

BUILD BOX ASSEMBLIES

- Ferrite cores

- Cut cores

- Toroids

- Laminations

- Custom magnetic windigs

- Open style toroids, series regulator inductors, output filtering chokes

- Ferrite EE core construction

- Ferrite E core construction

- SMT technology, single and double sided

- Mixed technology, single and double sided

- Through-hole technology and through-hole to SMT

- Engineering design, and circuit card layout

- Component selection

- Legacy production using lead based solder

- Design for manufacturability (DFM) and design for testing (DFT)

- Cable harnesses and card sets

- Wire leads and hardware

- Labeling and testing

- Electro-Mechanical assembly

- Electrical control panel and boxes

- Power supply and audio boxes

- Electrical and electronic enclosures

- Switch panels and control consoles

- Electronic sub-racks

- Equipment controllers

- Electric instrumentation

- Complete product assembly

- Purchasing design and distrubution

ENGINEERINGTESTINGMANUFACTURINGQUALITY ASSURANCE

- Printed circuit boards designed for manufacturability to reduce opportunities for defects, and to minimize manufacturing costs.

- Schematic compatibility with many packages

- Development of production optimum penalization

- Packaging design assistance

- Conversion of through hole to SMT

- Reverse engineering of old design

- RoHS conversion and engineering

- Can write test plans and do qualification testing

- EMI testing

- Temperature testing

- HALT

- HASS

- Life testing

- Shock and vibration testing

- ESS testing

- Prototype, low volume to full production

- MRP manufacturing software

- Transformer and coil winding in house

- Stencil printer

- SMT component placement machines

- Convection reflow oven

- Aqueous cleaning system

- ESD protection with humuididy control

- Solders certified to J-STD-001

- Statistical Process Control

- Manufacturing personnel certified to J-STD-001

- Through hole, surface mount, soldering, and rework training in house

- IPC-610 certified trainer and several specialists

- Quality system based on ISO9001-2008

- ITAR registered

- In process inspection along with 100% final electrical and hi-pot testing

- Thorough contract and specification review prior to release to engineering

- Qualified to MIL-STD-810, altitude, humidity, salt fog, dust (fire and sand) explosive atmosphere, immersion, shock, vibration, solar radiation, Halt, Hass, MTBF. Numbers, de-rating to NAVSO P-3641A

- Certifications / Standards include: MIL-STD-810, 461, 51 0-704, 1399 MIL-PRF-27, VDE, TUV

- Environmental screening for production including vibration and temperature cycling

- Calibration of test equipment and measurement equipment per ANSI/NCSLZ-541-1-1994 traceable to N.I.S.T.