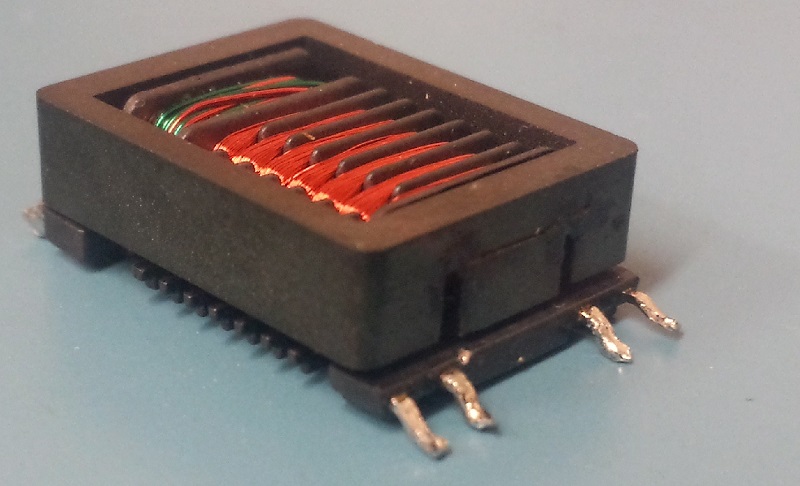

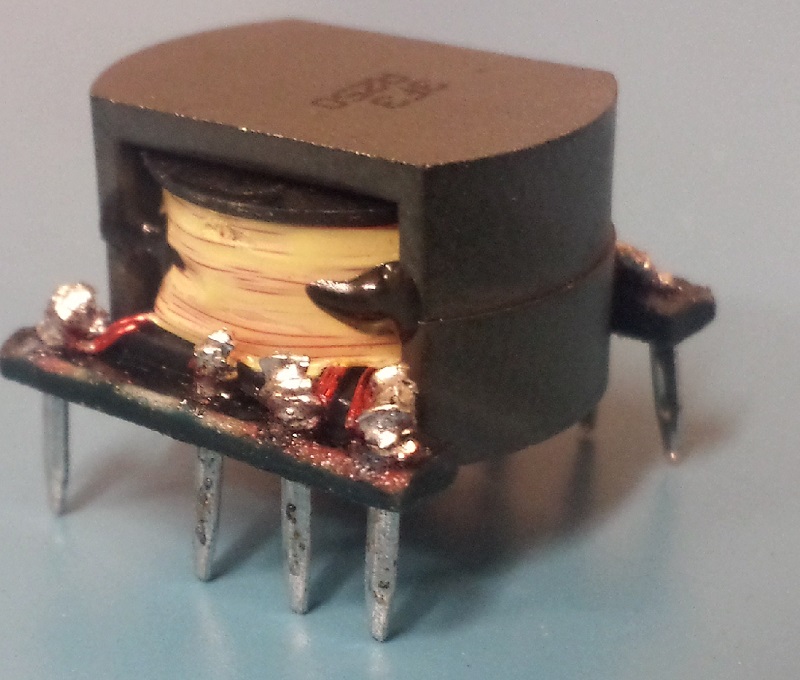

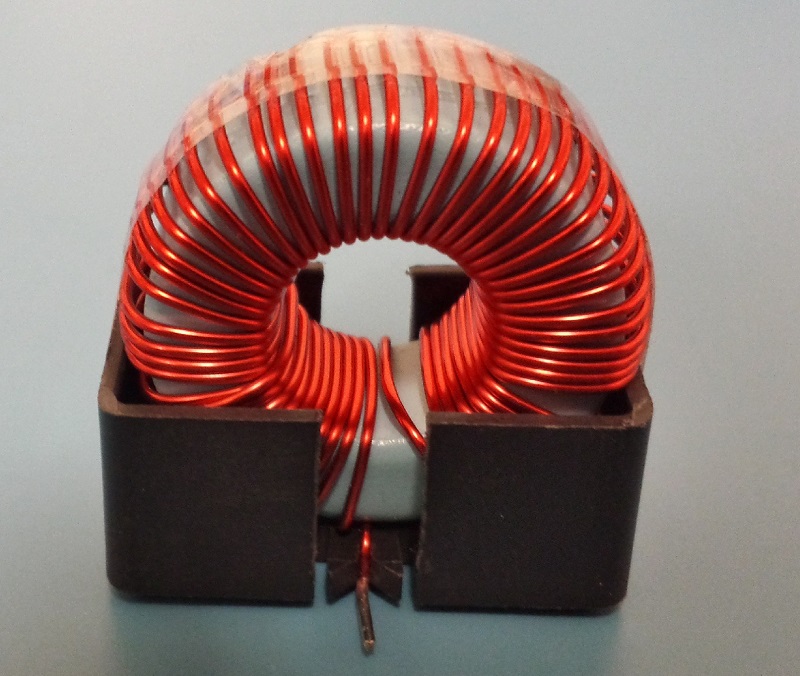

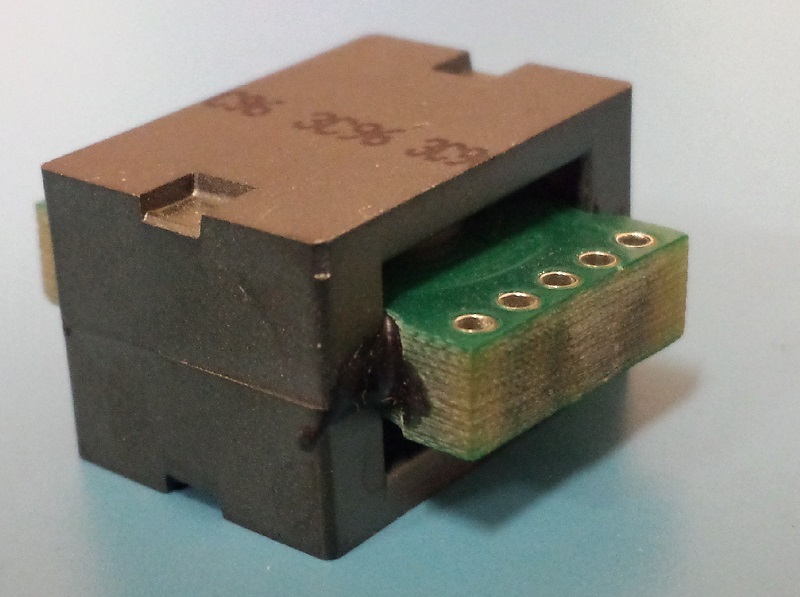

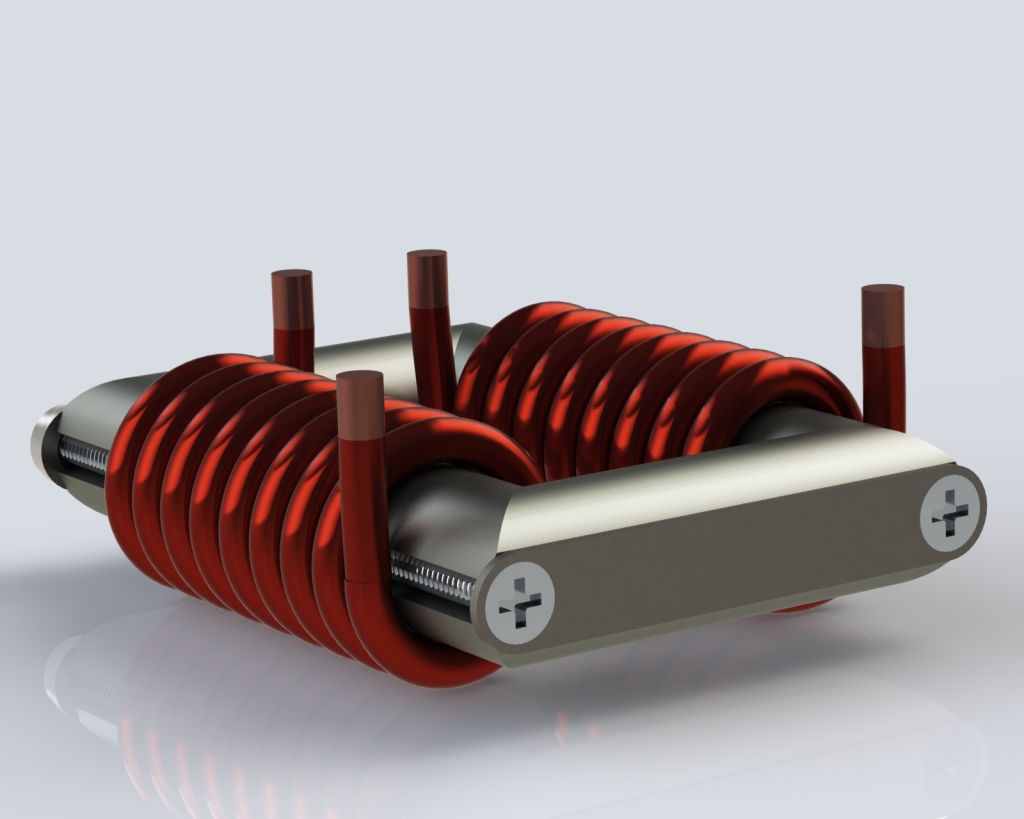

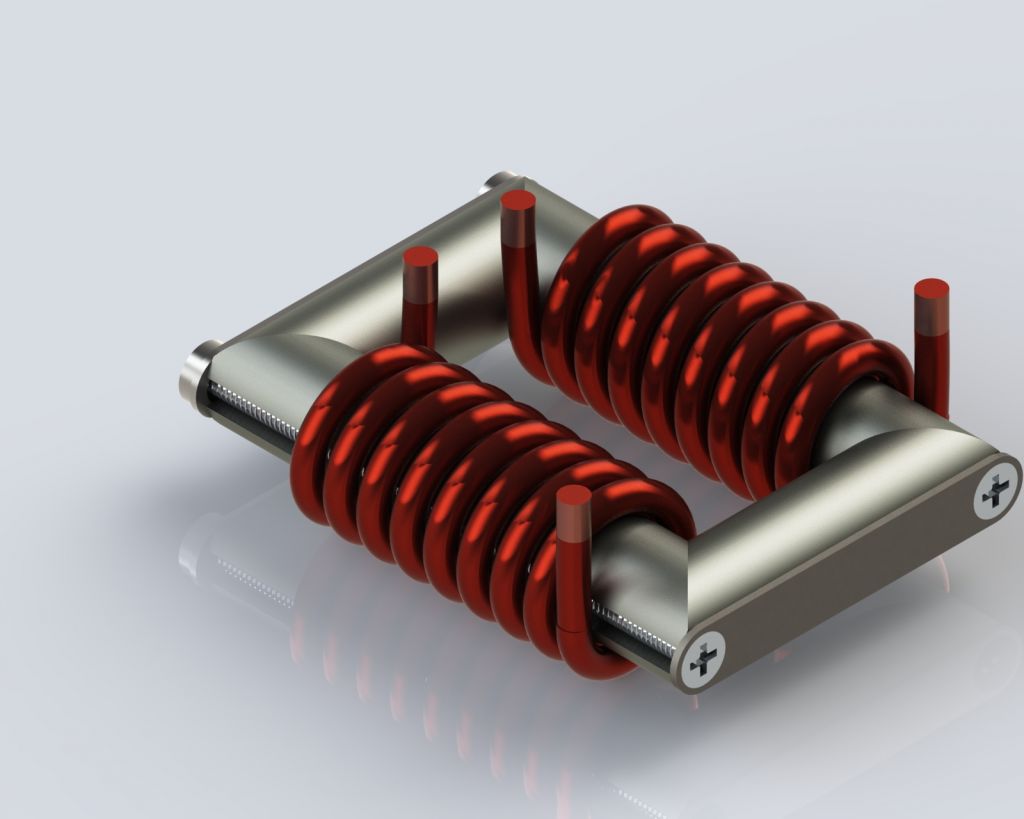

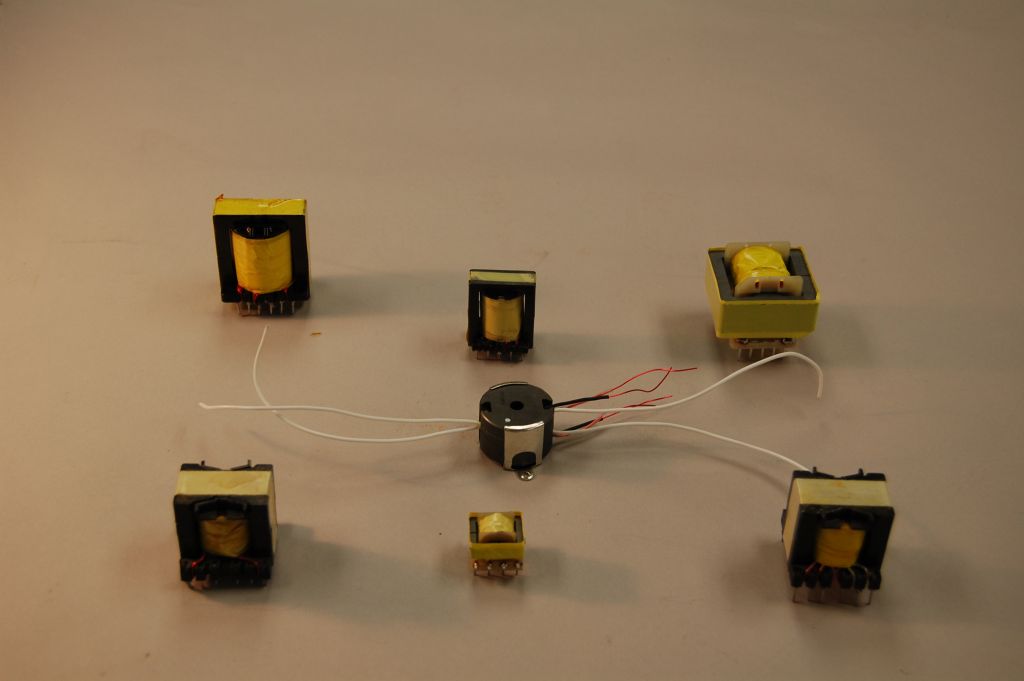

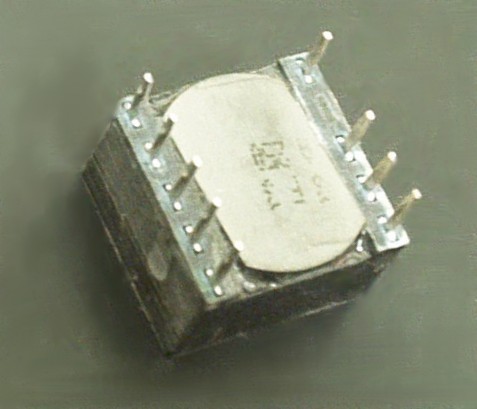

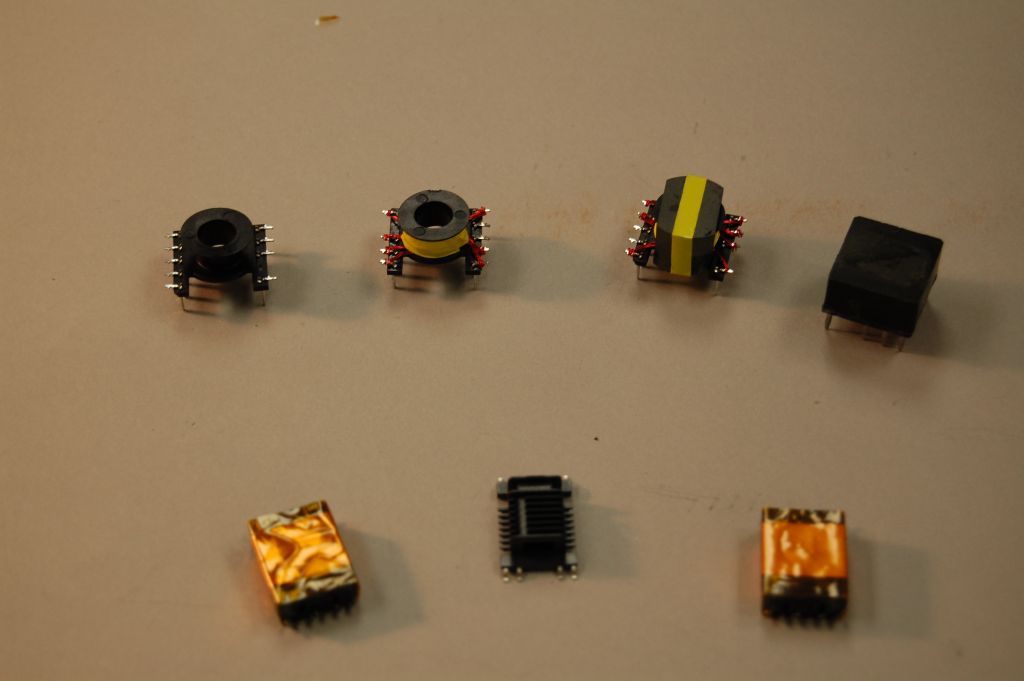

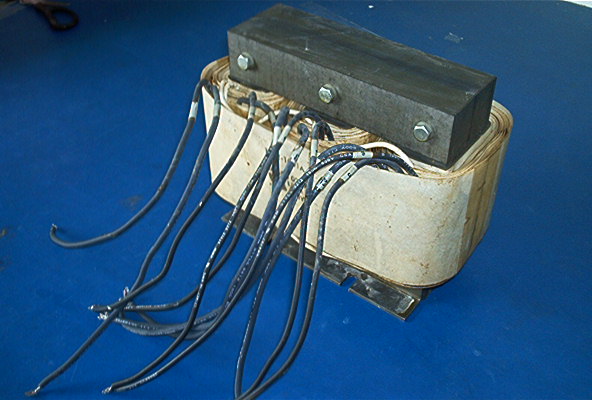

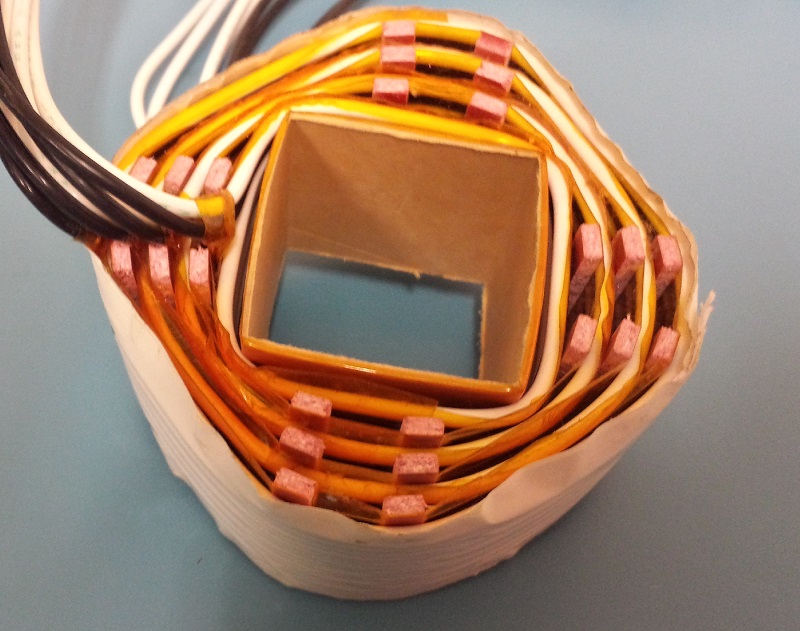

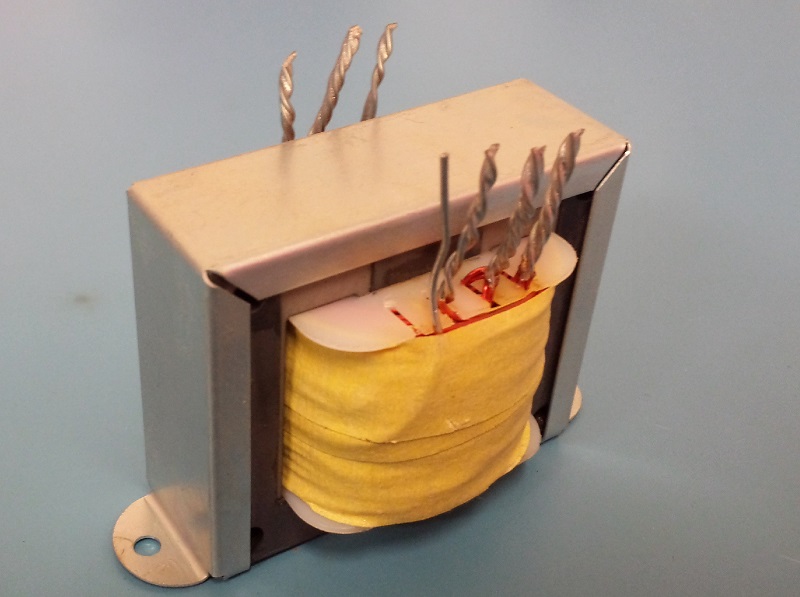

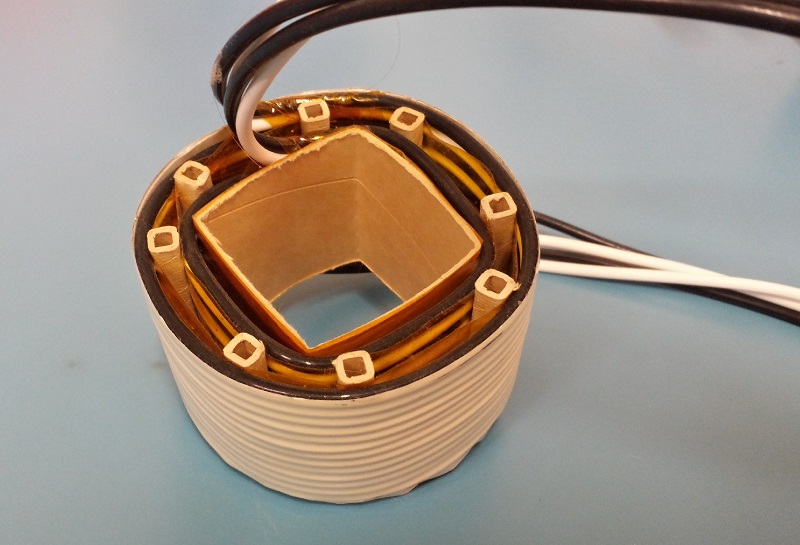

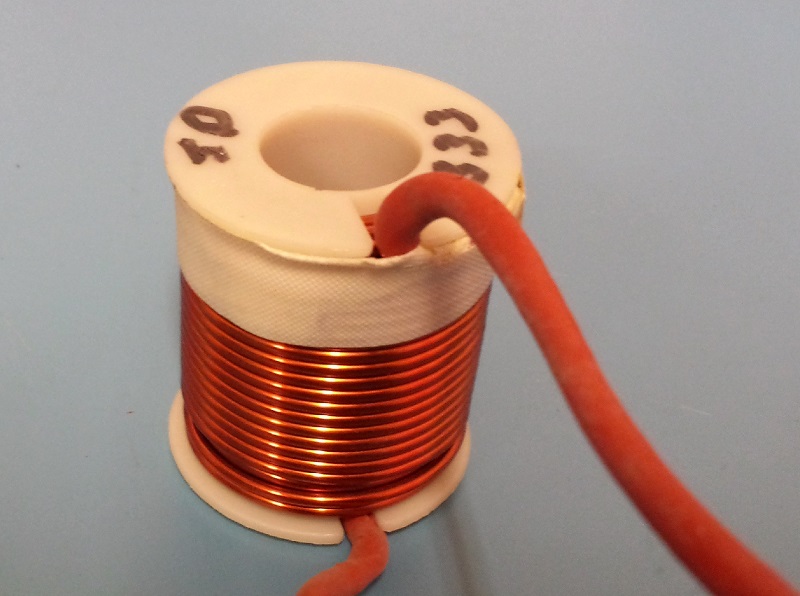

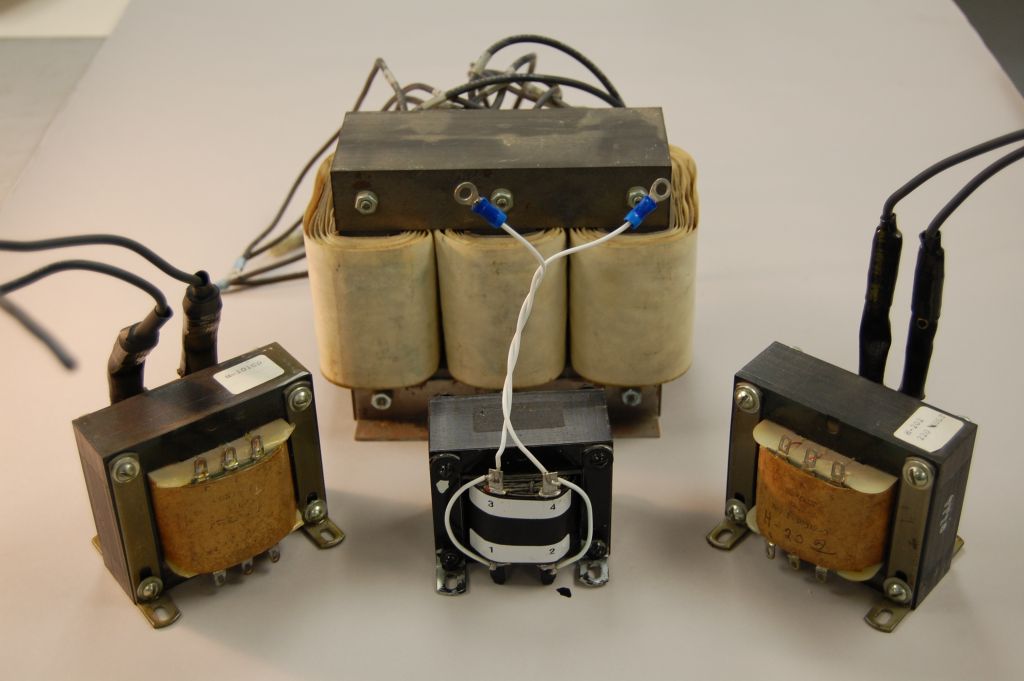

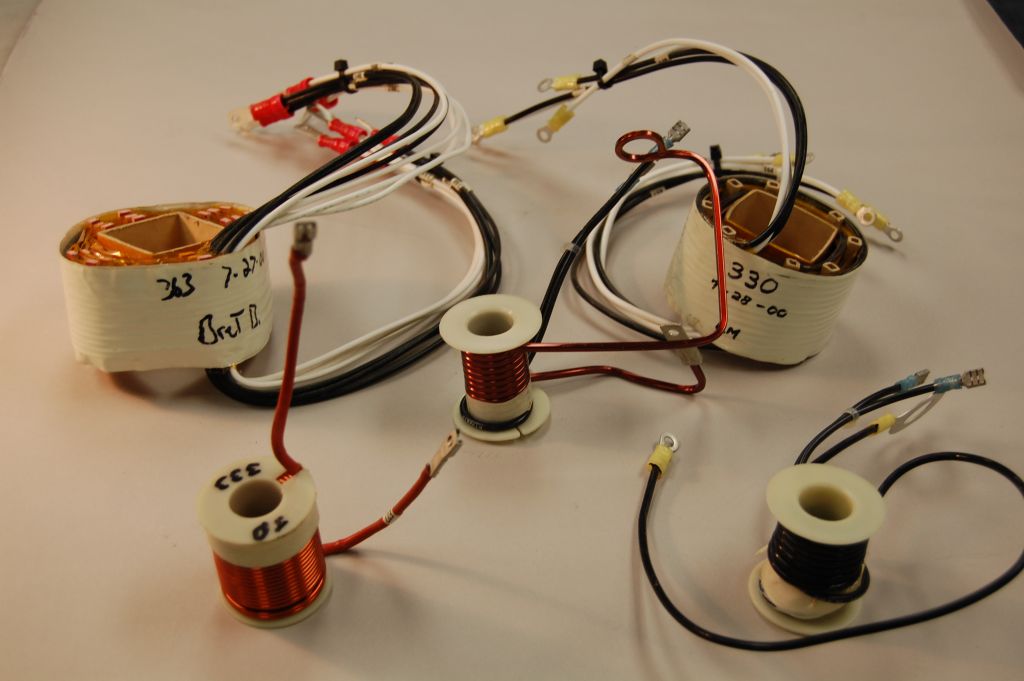

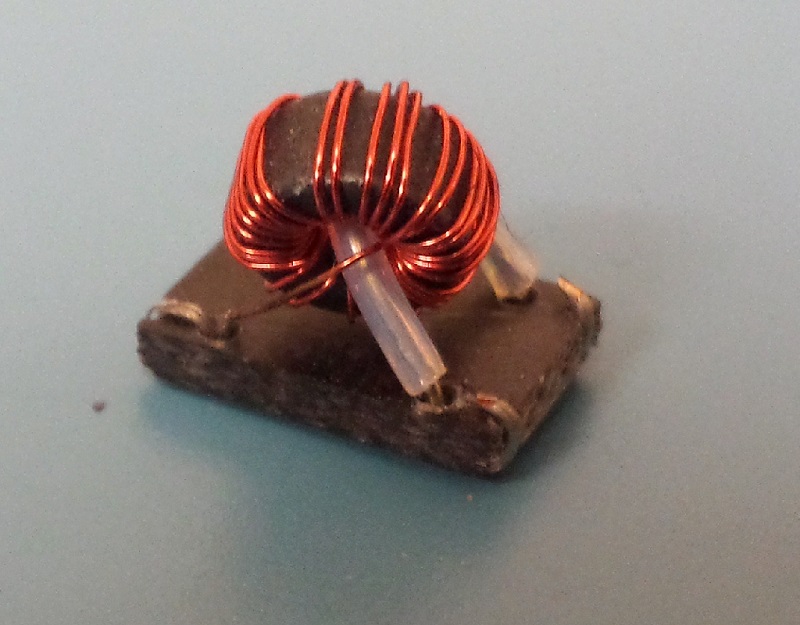

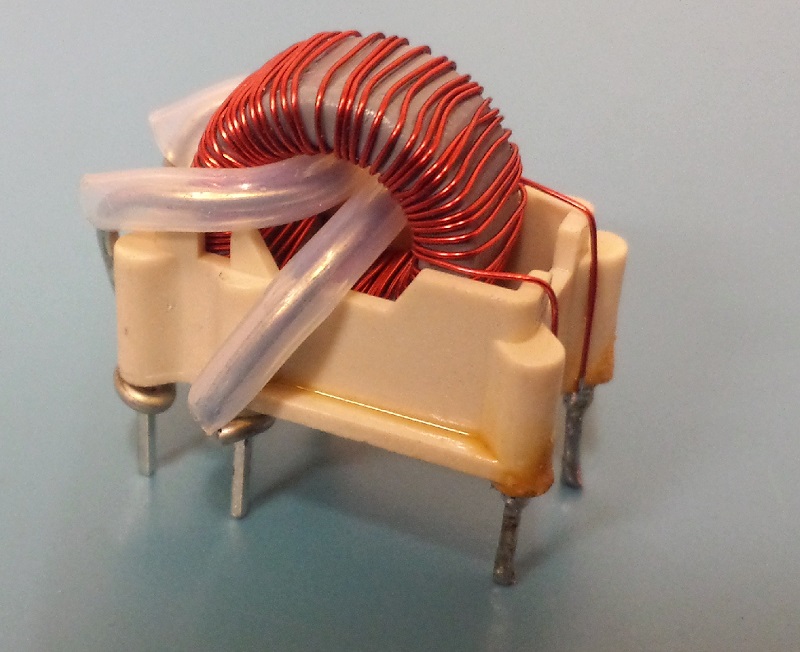

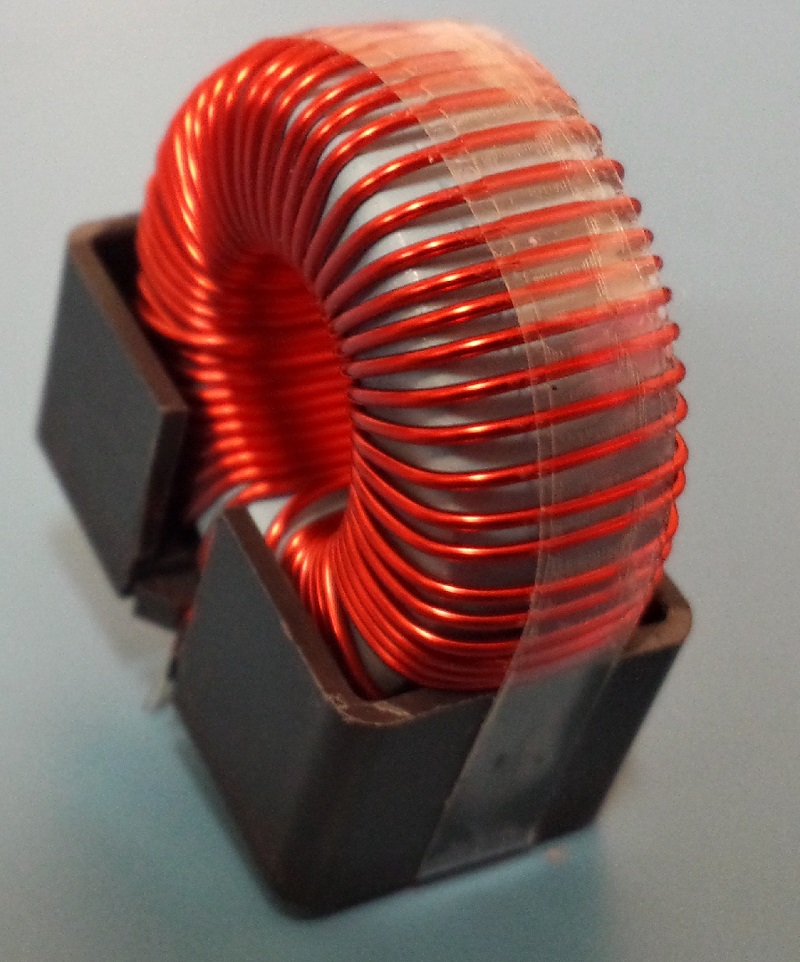

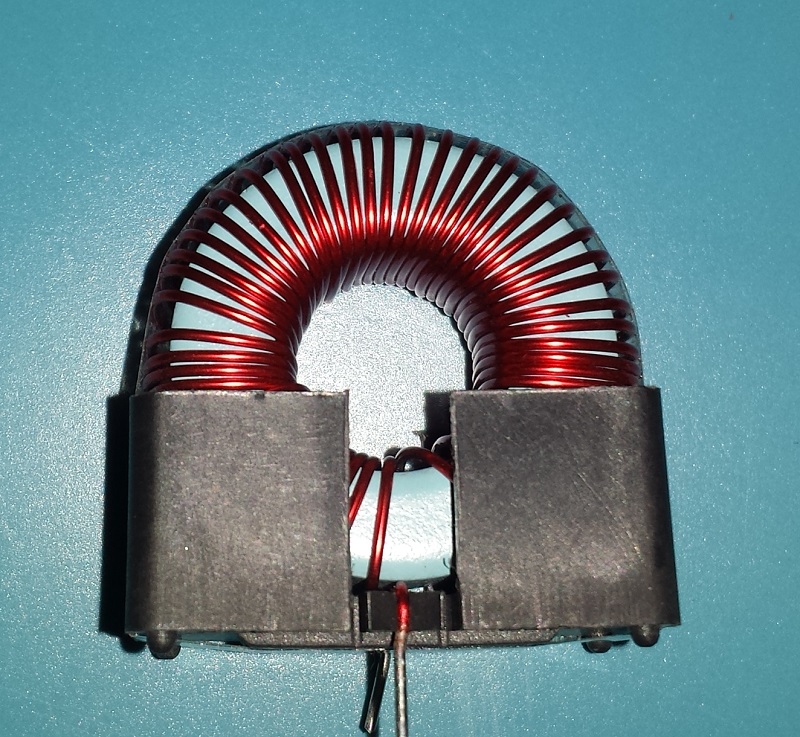

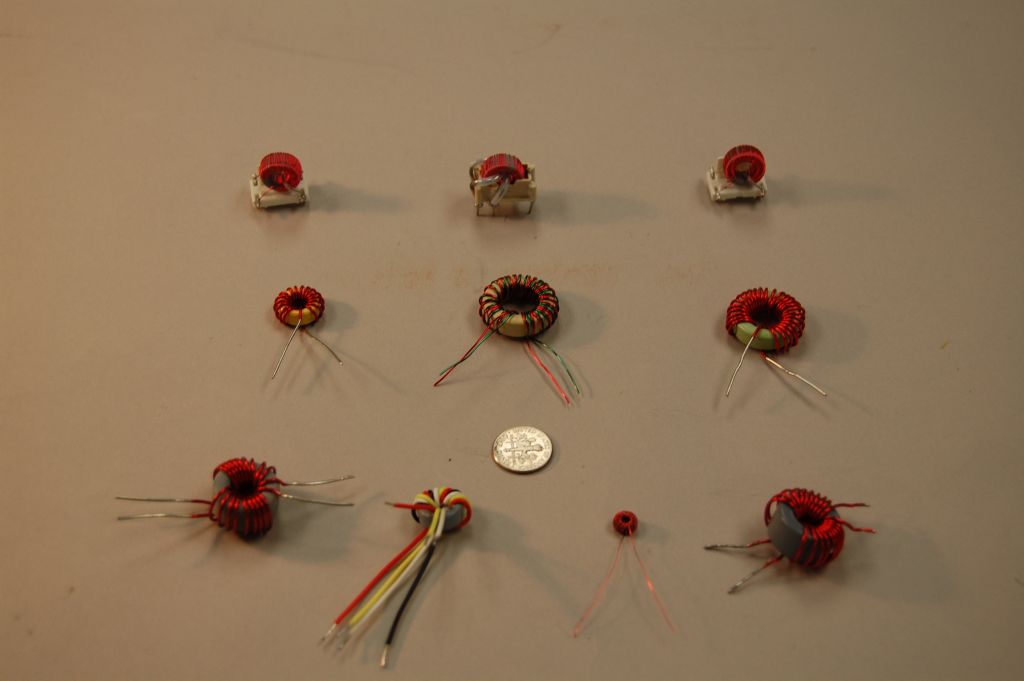

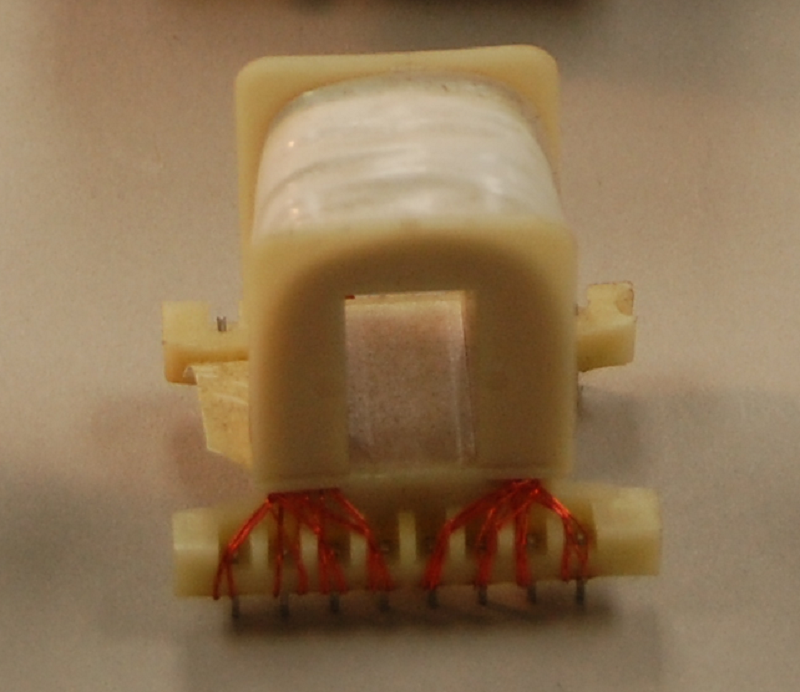

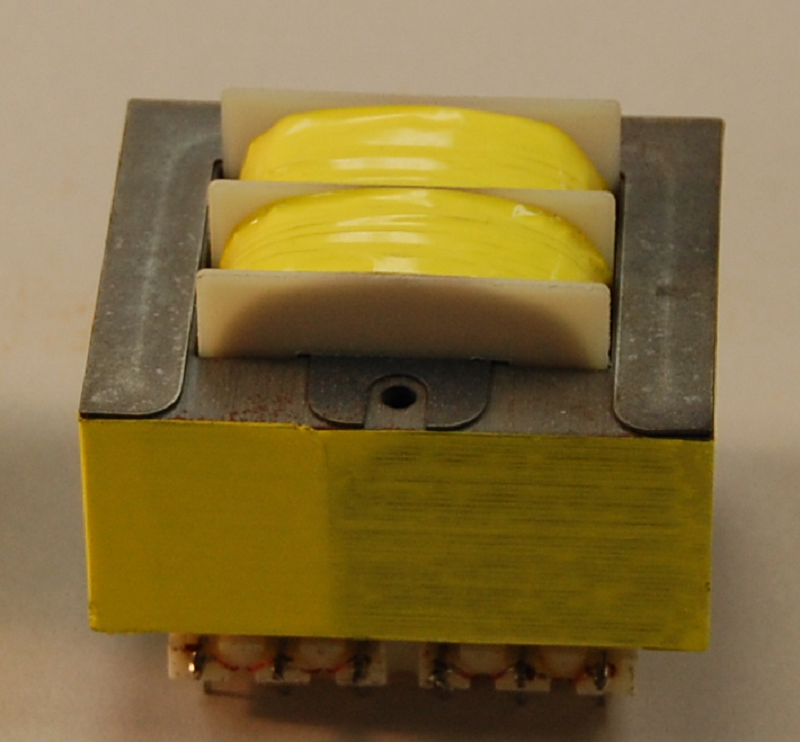

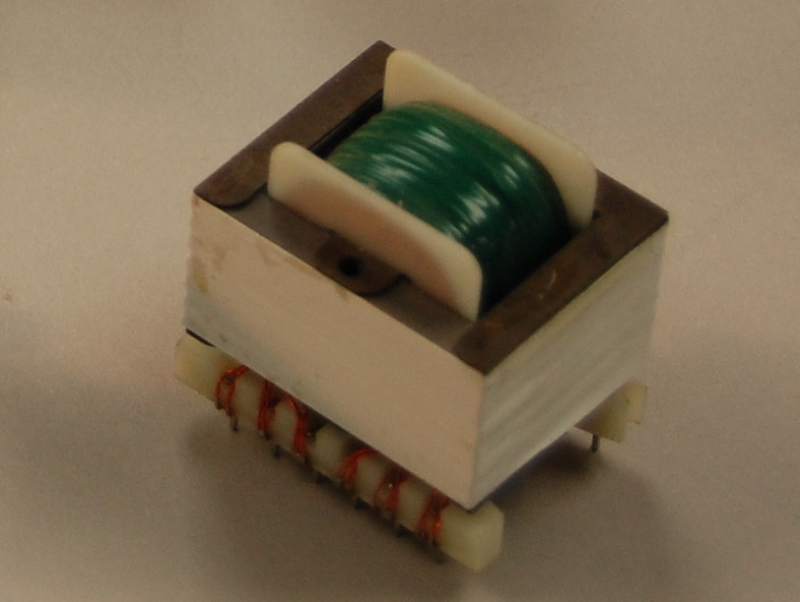

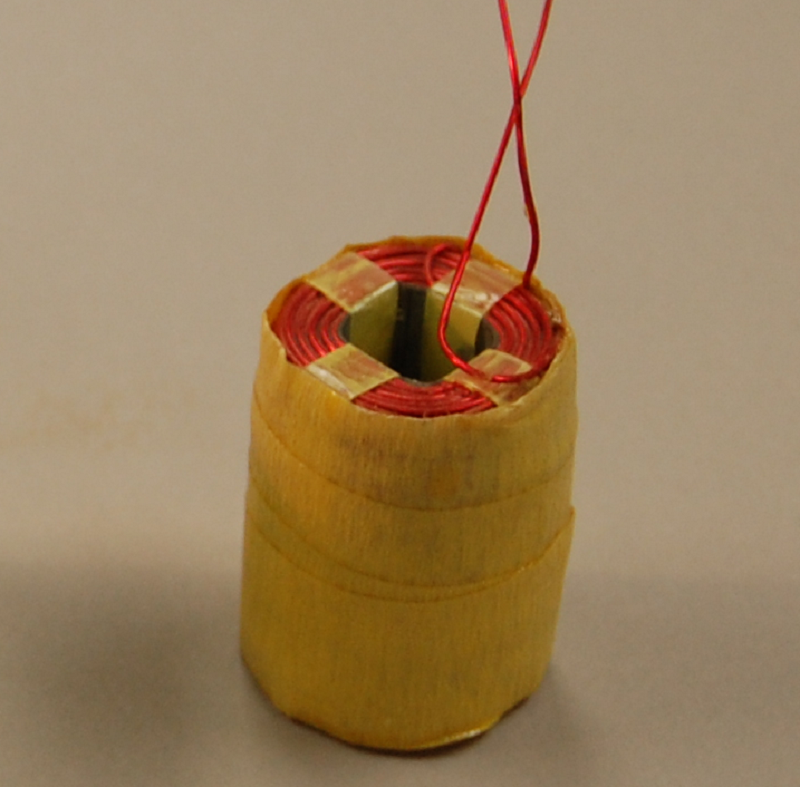

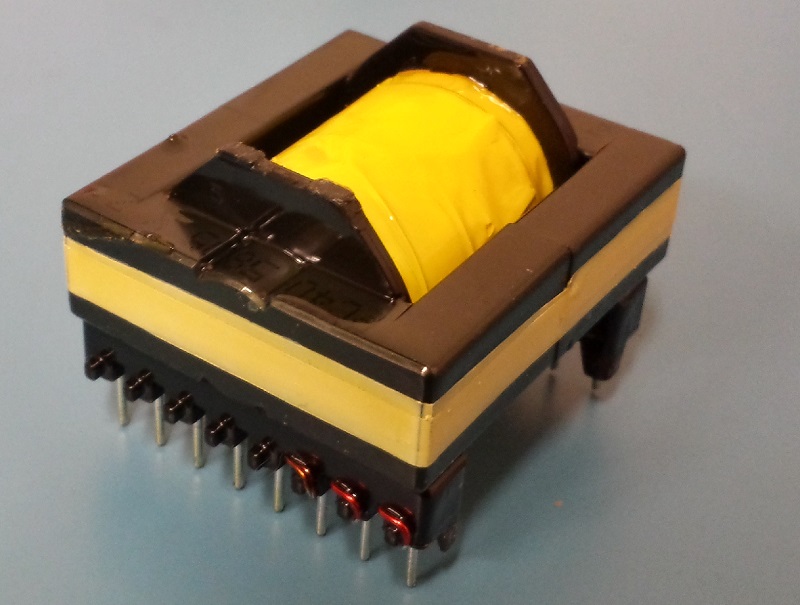

DCA specializes in all types of transformer design. Our knowledgeable staff is experienced in the design of most styles of transformer and inductor. DCA’s extensive experience in transformer design allows us to be confident that we can design and deliver a top quality transformer to meet almost any customer requirements.

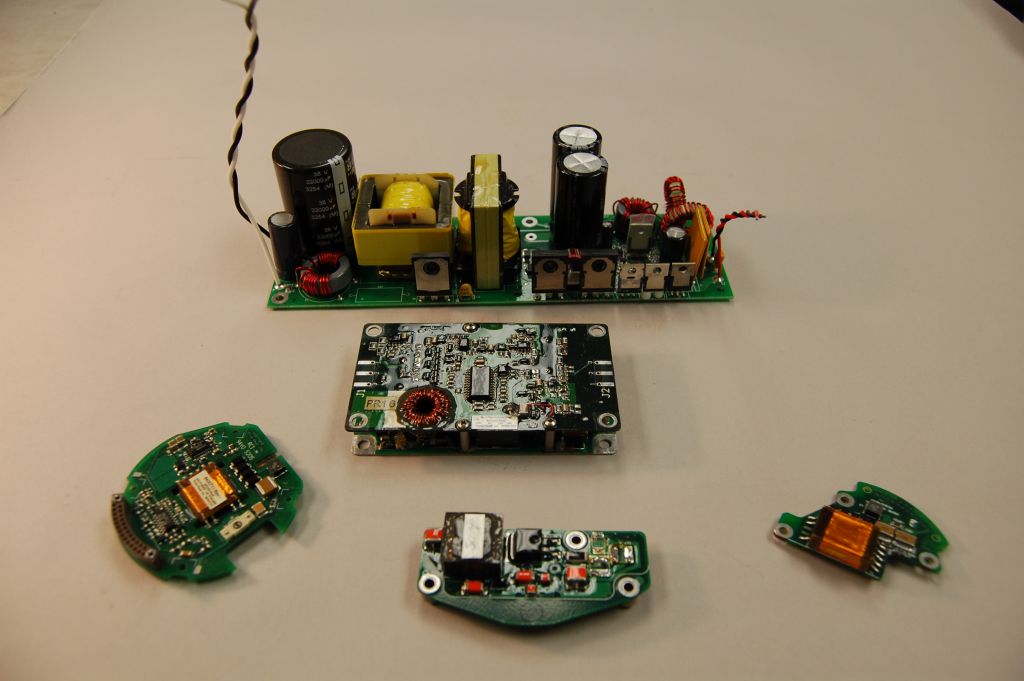

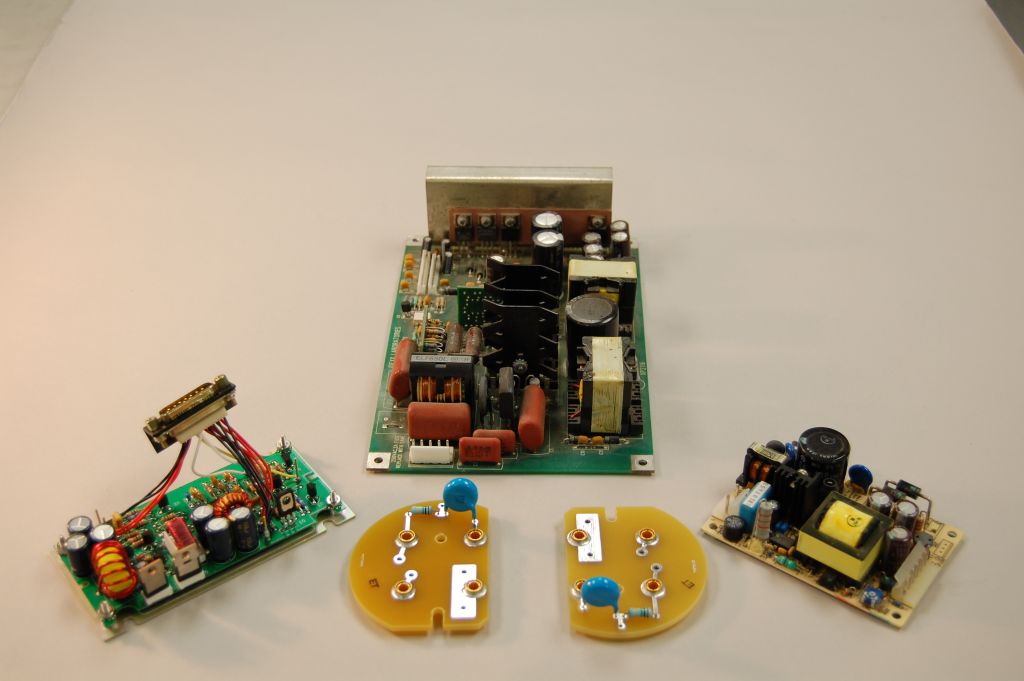

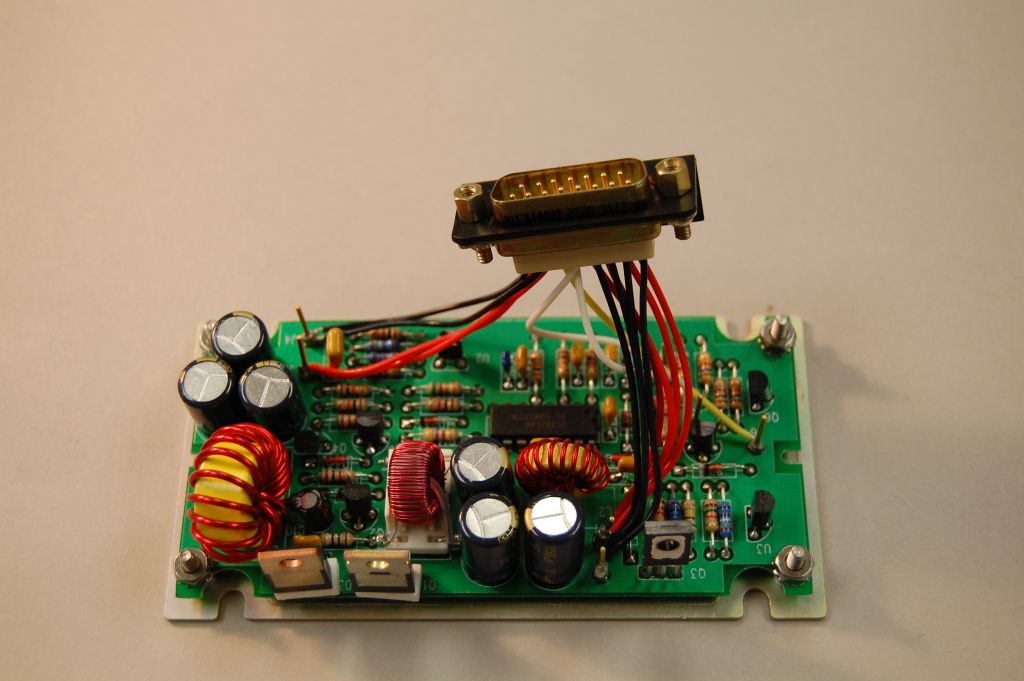

DCA provides fast, reliable, and affordable PCB production runs. DCA can provide PCB production services from one prototype PCB to high volume production consisting of thousands of units per month. Contact DCA today for a quote on your PCB production run.

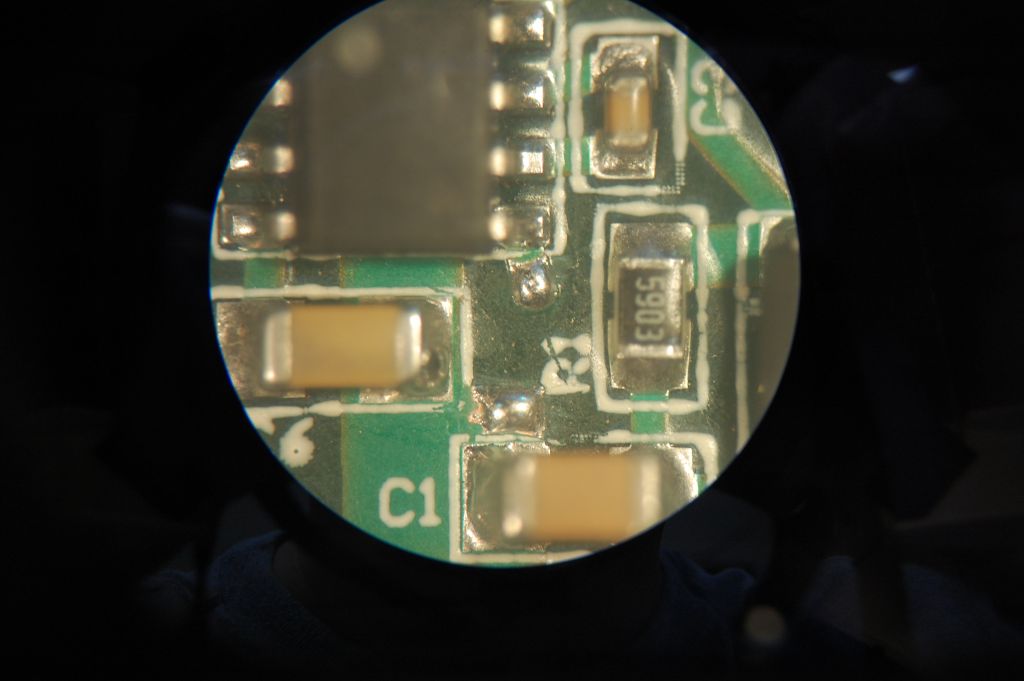

Your PCB assembly and electronics manufacturing will be performed in the United States by IPC-trained workers. Our on site engineers will monitor the PCB design and assembly at all points to assure the quality of the PCB build and design. DCA’s excellent quality assurance department will ensure the quality of each and every PCB delivered by DCA. We work with all major OEM and franchised distributors to ensure the most cost effective PCB build available.

SERVICES

DCA is a fully modern electronic manufacturing services (EMS) company. We offer the full range of services you need to assemble your printed circuit board, including:

- Surface Mount Pick & Place Technology (SMT)

- Through Hole Selective Soldering

- Screen Solder Paste Printing

- Hand Solder & Assembly Services

- Full Functional Test Capabilities

- RoHS Bill of Material Conversions

- Conformal Coating and Potting

- Component selection

- Engineering PCB layout

- Reverse engineering PCB layout

- Throughole to SMT conversion

PCB DESIGN CAPABILITIES

| Types of PCB Assembly | Surface Mount, Through Hole, Mixed Assemblies |

| Lead or Lead Free | |

| Single or Double Sided | |

| No Clean Fluxes, Lead or Lead-free | |

| Programs | Prototyping and Fast Turn |

| Full Turnkey Assembly | |

| Consignment / Kanban / Order-Fulfillment Programs | |

| Labor Only / Customer Owned Components | |

| Components | Passives parts, smallest size 0603 |

| Fine pitch to 8 Mils | |

| QFN, POP and Leadless chips | |

| Connectors and terminals | |

| Accepted Component Formats | Reels, Digi-Reels |

| Cut tape (allow leader or overage) | |

| Tube and tray | |

| Loose parts and bulk. | |

| PCB Board shape | Rectangular |

| Round | |

| Slots and Cut outs | |

| Complex and Irregular | |

| PCB Board type | Rigid FR-4, Rigid-Flex Boards |

| Flexible, Flat-Flex (FFC) | |

| PCB Assembly process | Leaded process |

| Lead-Free (RoHS) | |

| Testing capabilities | |

| AOI (Automated Optical Inspection) | |

| ICT (In-Circuit Test) / Functional testing / Bed of Nails | |

| Design file format | Gerber RS-274X |

| BOM (Bill of Materials) (.xls, .csv, . xlsx) | |

| Oven profile | Standard Reflow |

| Custom Reflow | |

| Turnaround time | * days for only PCB assembly |

| * days for turnkey PCB assembly |

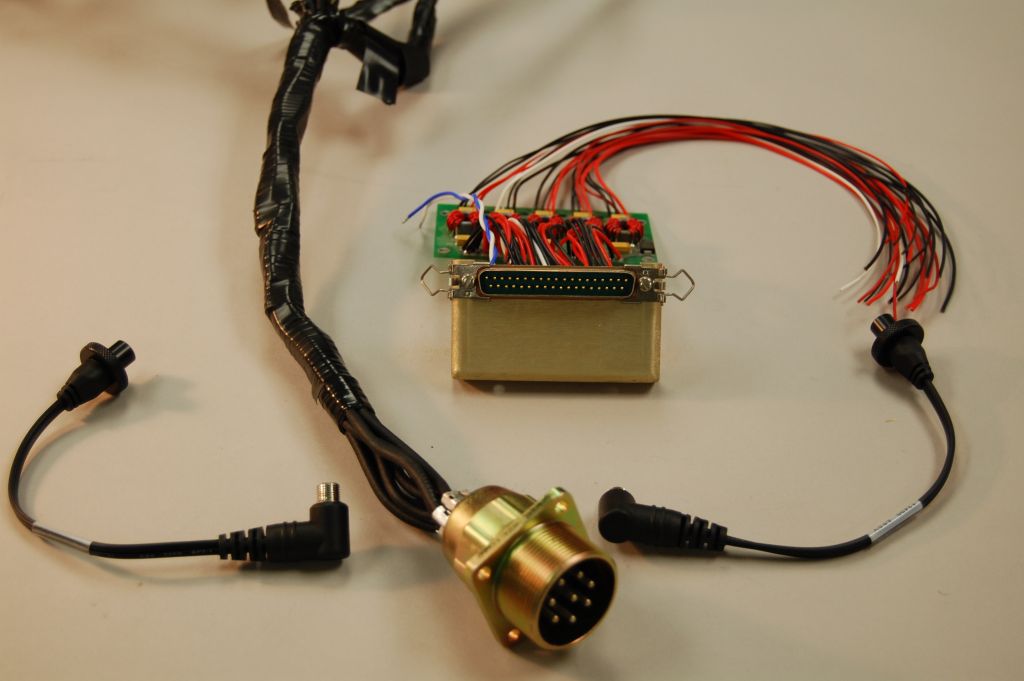

DCA offers wire harness assembly of all shapes and sizes. Whether you need a create custom design or have a strict specification to follow DCA can provide a wire harness assembly to suit your needs. DCA offers labeling and 100% testing services on all of its wire harness designs.

DCA’s experience in varying high stress fields has given DCA the experience necessary to develop box builds for all project needs from a simple consumer grade box to IP67 sealed waterproof, or vacuum evacuated cases for extreme temperatures. Contact DCA today for a quote on a box build design to suit almost any needs that will meet or exceed performance expectations in any desired environment

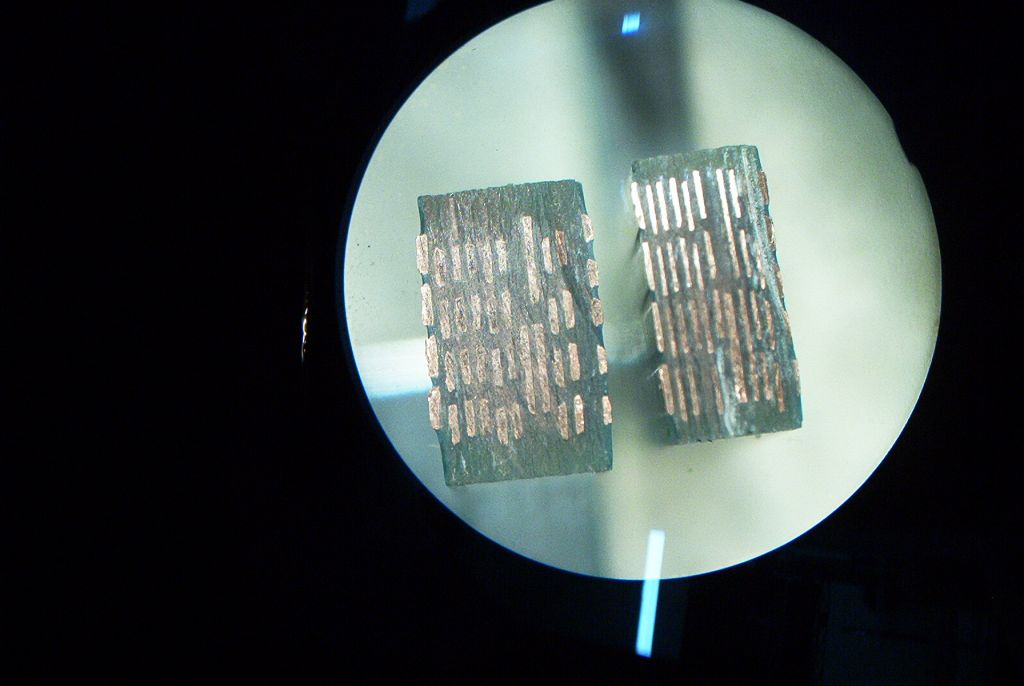

TESTING

DCA provides testing services to ensure the reliability of your product. DCA’s knowledgeable staff is well versed in the design, manufacture, assembly, programming and proper use of a wide variety of 3rd party and custom test equipment. DCA’s background in the design and development of various mission critical devices provides an excellent base of knowledge and experience in delivering working products to our customers with minimal fallout.

Full functional testing ensures near 100% product end use reliability. Functional testing tests the PCB’s functionality and ensures proper circuit behavior. All functional test results are recorded, and at the customer’s request can be and serialized and delivered with the product. Functional testing can be combined with statistical process control allowing DCA to deliver the most reliable products and processes possible.

ESS/Thermal testing tests the effects of environmental stress on your product to ensure that the product will function correctly in extreme environments. DCA has experience in the use, programming, design, and manufacture of various ESS testing systems. DCA has designed custom cooling/heating racks, and automated electrical testing systems, and frequently uses third party ESS testing systems. This allows DCA to confidently ensure the quality of the test, the test fixture, and the quality and ability of the product being tested to function in extreme environments.

Burn-in testing is the process of testing a product over a length of time, usually under varying environmental stress. Burn-in testing is one of the best ways to stress your product while ensuring that it remain in proper working condition throughout the length of the test. Typically a burn in test is run for at least 3 hours while varying from cold temperature extremes to hot, and back. DCA can design and run a burn in test for your mission critical product to guarantee reliability through temperature extremes.

DCA offers both visual and AOI inspection. Full inspection ensures that your product is free from manufacturing defects which could later manifest as product failure. DCA’s background in mission critical products has lead to a team of experienced inspectors with superb attention to detail. This commitment to quality ensures that only the best quality products are delivered to our customers. DCA’s in house inspection team is committed to quality production. Their attention to detail and quality ensures that DCA can be confident in its ability to deliver the best product possible to our customers.

DCA has designed custom test fixtures for many different design requirements. DCA’s commitment to the quality of our products has lead to the need to develop test fixtures, and procedures for various purposes, ranging from simple continuity testing, to full product testing to designing custom environmental stress fixtures to test a products ability to function over a range of temperature extremes. Contact DCA today to receive a quote for all of your product testing needs